The ability or ‘Tonnage’ of the brake push refers back to the most number of force it may exert. The fabric thickness, kind and bend radius dictate the quantity of tonnes of pressure are essential. Width refers back to the optimum bend size the push can accomplish. A normal brake push by way of example, can be 100T x 3m (“Press Brakes”).

It is sweet observe to make sure that all bend radii on a certain section are equivalent, as this significantly simplifies tooling arrange and lessens Expense.

You’ll also lower your energy bills and maybe even see an increase on your property’s resale benefit. Some varieties of metal roofs cost noticeably over Many others, so weigh the advantages of Just about every to pick which substance and price selection is most effective for you personally.

Equally metal and asphalt shingle roofs may be good selections for your home. The most important variances lie in the cost and repair service.

The melted metal of the two factors fused to form a strong relationship. Typical sheet metals like chrome steel and aluminum have good weldability, Despite the fact that different metals could weld superior with specified types of welding: arc, electron beam, resistance, and so on.

Tonnage - as pointed out, presses have a utmost tonnage ability, components for example bend radius, material Attributes, product form and bend size all add to simply how much pressure is needed to make the bend. Check out with our engineering staff right before committing to the design you're unsure of.

This guides think about the main sheet metal fabrication processes and points out how they do the job and what they are used for.

Low priced & Tiny to No Tooling - Mainly because of the developments in technological know-how, CNC slicing and bending cuts down the manual labour needed to create sections, the sheet metal bending process has benefited from this tech a lot more than most, with CNC controlled tooling, elements is usually produced by a lot less-experienced employees in fewer time, all resulting in a reduce conclusion cost.

The percentage could boost if your private home has complex rooflines or many dormers, or the roofing itself is hard to set up.

Drinking water can get past metal joints; The ultimate way to cease it is actually using a superior-temperature, waterproofing underlayment stuck to your complete roof deck. This materials also seals all over Every fastener penetrating the roof.

A single significant general guideline is that the skin radius of curls really should be at least two times the thickness on the sheet metal. Additionally, the spacing of holes from curls have to be no less than the curl radius additional towards the sheet metal thickness.

This guideline, paired with our other articles exploring the sheet metal and bending processes will provide you with a grounding to be familiar with and discuss your solution’s demands with sheet metal makers for instance ourselves.

REALITY: Hail can hurt roofing of any variety, When the hailstones are sufficiently big. In read more regions exactly where hail takes place usually, you would like metal roofing with a category 4 score. This rating suggests which the roofing has withstood UL’s most significant impression take a look at typical—a two-inch diameter steel ball dropped from 20 toes—without the need of tearing, fracturing, cracking, or splitting.

The objective of sheet metal bending approaches will be to condition sheet metal into its supposed varieties. Various factors play a role in deciding which sheet metal bending method is optimal for a provided undertaking.

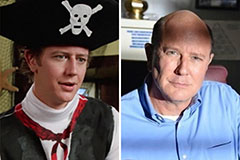

Judge Reinhold Then & Now!

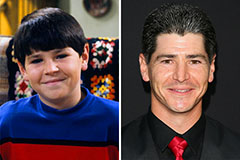

Judge Reinhold Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!